Tower Cranes: The Backbone of Modern Construction | Types, Functions & Safety

Discover how tower cranes revolutionize construction. Learn about their components, types, safety protocols, and role in building skyscrapers. Perfect for industry professionals and enthusiasts.

Introduction to Tower Cranes

Tower cranes dominate city skylines, symbolizing progress in construction. These engineering marvels lift heavy materials like steel beams and concrete slabs to staggering heights, enabling the creation of skyscrapers, bridges, and infrastructure. This article explores how tower cranes work, their types, safety standards, and why they’re indispensable in modern construction—optimized for SEO to help you rank for keywords like “tower crane types” and “construction crane safety.”

What is a Tower Crane?

A tower crane is a fixed crane used to hoist heavy loads vertically and horizontally. Its tall, vertical mast and horizontal jib provide unmatched reach and precision, making it ideal for high-rise projects.

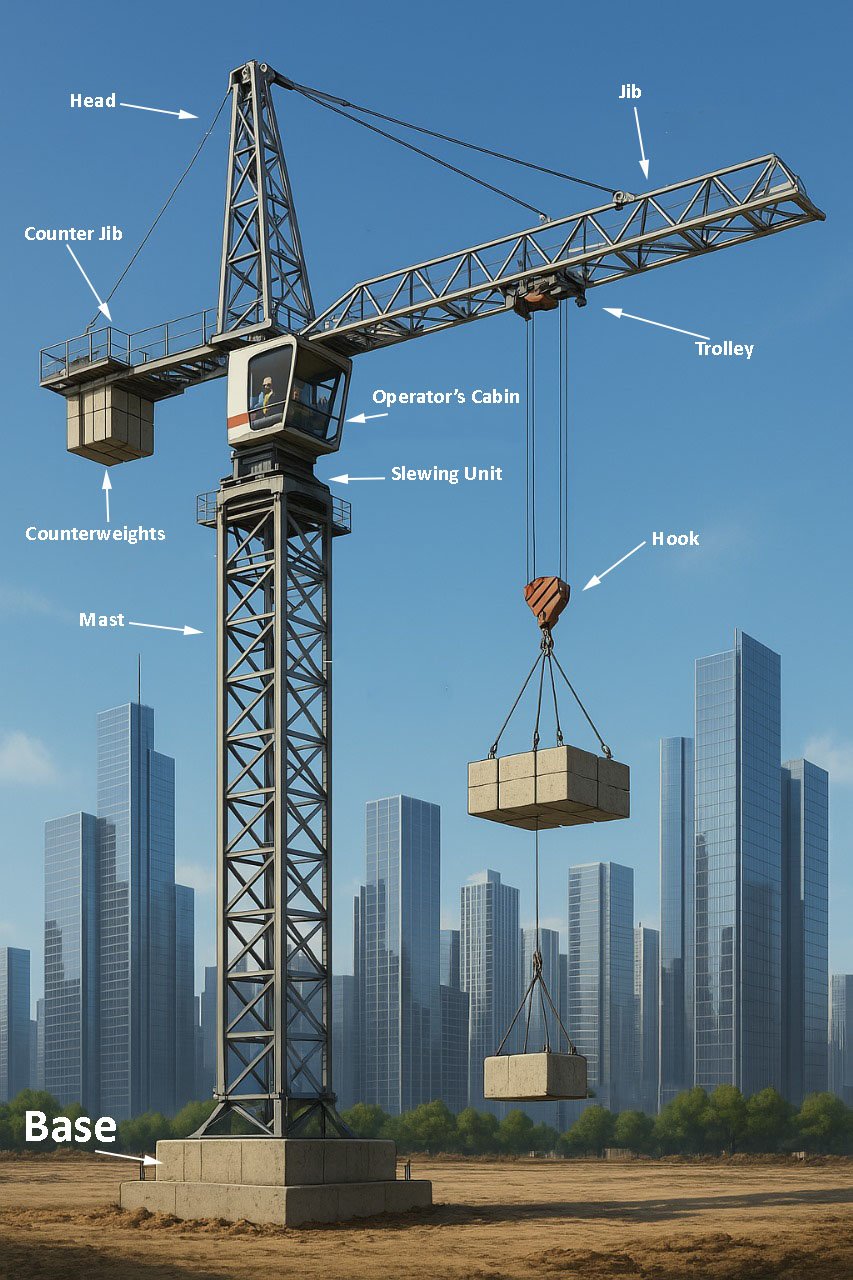

Key Components of a Tower Crane

Base/Mast: Anchored to a concrete foundation, the mast provides stability and height.

Slewing Unit: Allows the crane to rotate 360 degrees.

Jib (Working Arm): The horizontal beam that carries loads.

Counter Jib: Holds counterweights to balance the crane.

Trolley & Hook: Moves along the jib to position loads.

Operator’s Cab: The control center, often located near the slewing unit.

How Do Tower Cranes Work?

- Assembly: Built on-site using mobile cranes. Sections are added incrementally.

- Climbing Mechanism: Hydraulic systems extend the mast as the building grows.

- Operation: Operators use joysticks and load indicators to lift, swing, and place materials.

- Dismantling: Disassembled in reverse order once the project concludes.

Types of Tower Cranes

Hammerhead (Flat-Top) Crane

Fixed horizontal jib.

Ideal for wide, open sites.

Luffing Jib Crane

Adjustable angled jib.

Perfect for cramped urban areas.

Self-Erecting Crane

Compact, automated assembly.

Used for low-rise projects.

Safety Measures for Tower Cranes

OSHA Compliance: Regular inspections and load testing.

Anti-Collision Systems: Sensors prevent jib collisions.

Wind Speed Monitoring: Halts operation during high winds.

Operator Training: Certified professionals only.

Load Limits: Strict adherence to manufacturer guidelines.

Why Tower Cranes Are Vital in Construction

Efficiency: Move tons of materials swiftly.

Reach: Access heights unreachable by mobile cranes.

Cost-Effective: Reduce labor and timeline costs.

Versatility: Adaptable to residential, commercial, and industrial projects.

The Future of Tower Cranes

Innovations like remote-controlled operation, AI-driven load optimization, and eco-friendly electric models are transforming the industry. Expect smarter, safer cranes as automation and sustainability take center stage.

Conclusion

Tower cranes are the unsung heroes of construction, enabling humanity to build taller and faster. Understanding their mechanics, types, and safety protocols ensures efficient and accident-free projects. Whether you’re a contractor, engineer, or enthusiast, mastering tower crane operations is key to modern construction success.